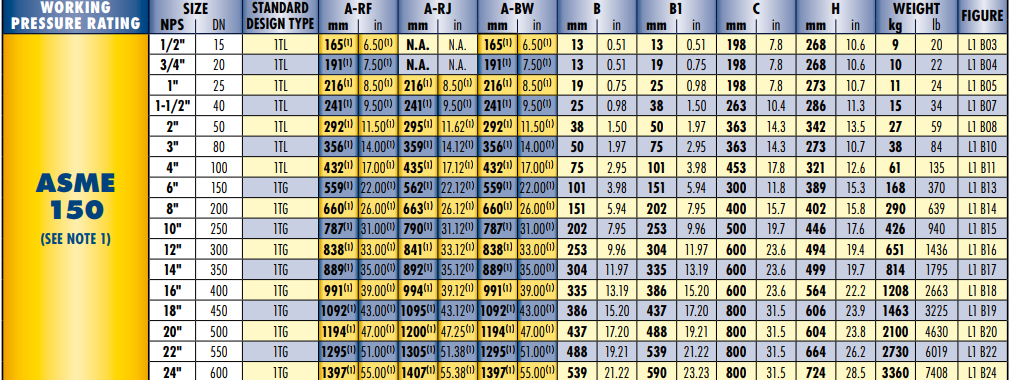

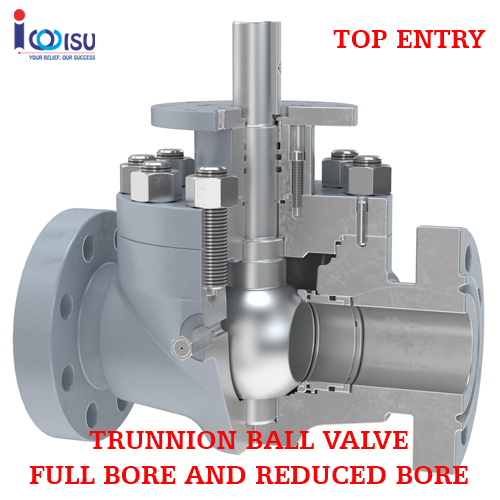

TOP ENTRY REDUCED TRUNNION BALL VALVES CL150

REDUCED BORE TRUNNION BALL VALVES CLASS 150

REDUCED BORE TRUNNION BALL VALVES

BASIC CONFIGURATION

ASME INTEGRAL FLANGED AND WELDING ENDS

TRUNNION BALL VALVE CLASS 150 TOP ENTRY REDUCED BORE

DESCRIPTION

The trunnion ball valve is a form of quarter-turn valve which uses a hollow, perforated and fixed/supported ball to control flow through it.

A trunnion mounted valve means that the ball is constrained by bearings and is only allowed to rotate, the majority of the hydraulic load is supported by the System constraints, resulting in low bearing pressure and no shaft fatigue. The line pressure drives the upstream seat against the stationary ball so that the line pressure

forces the upstream seat onto the ball causing it to seal.

The mechanical anchoring of the ball absorbs the thrust from the line pressure, preventing excess friction between the ball and seats, so even at full rated working pressure operating torque remains low. This is particularly advantageous when the ball valve is actuated because it reduces the size of the actuator and hence the overall costs of the valve actuation package.

Cataloge: TOP ENTRY REDUCED TRUNNION BALL VALVE CLASS 150 CLASS 300

PRODUCT FEATURES: TRUNNION BALL VALVE CLASS 150 TOP ENTRY REDUCED BORE

1. Standard double block sealing performance.

2. Full die forged structure for all pressure containing parts.

3. Flanged valves are provided with flanged integral with closure member.

4. Standard primary gasket design is OR AED type, secondary emergency seal always provided for firesafe purpose.

5. High quality stem gasket for reliable tightness and low emission performance.

6. Use of low seat-ball friction materials and surface finish for reliable sealing and long service life.

7. Best-in-Class CV values.

8. Standard split & bolted design for body-closure connection.

9. Low operation torque design.

10. Static conduction spring is used as standard between the stem and the ball (Antic-Static Device).

11. Anti blow-out proof stem design

Applicable Standards: TRUNNION BALL VALVE CLASS 150 TOP ENTRY REDUCED BORE

- DESIGN: API 6D – ASME B16.34 – ISO 17292 – API 608

- INSPECTION & TESTING: API 598

- MARKING: MSS SP-25

- RATING: ASME B16.34

- With possible derating for high temperature based on seat material.

- FUGITIVE EMISSION: ISO 15848

PRODUCT FEATURES: DESIGN TRUNNION BALL VALVE TYPE CLASS 150 TOP ENTRY

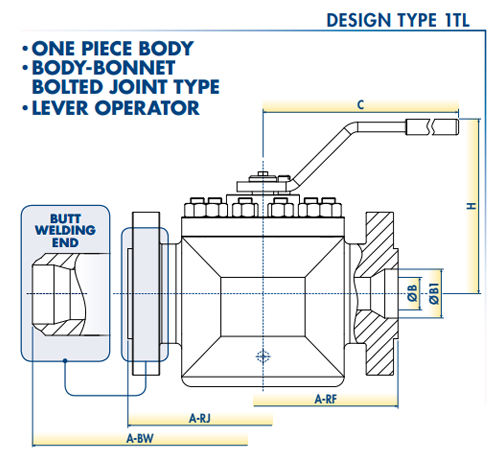

DESIGN REDUCED TRUNNION BALL VALVE TYPE CLASS 150 TOP ENTRY

Standard O-Rings in Viton with AED properties.

NOTE: Face-to-Face acc.to ASME B16.10 related to class 600

- GLAND COVER & SHAFT TRUNNION

- LEVER OPERATOR

- CONNECTION: FLANGED END, BUTT WELDING END

DIMENSION: TRUNNION BALL VALVE CLASS 150 TOP ENTRY REDUCED BORE

DIMENSION REDUCED TOP ENTRY TRUNNION BALL VALVE CLASS 150