A Pneumatic Actuated Flanged Bellows Sealed Valve CF8 is a globe-type control valve designed for precise steam flow regulation and zero external leakage. By combining a bellows sealed stem design with a pneumatic actuator, this valve is widely used in steam, thermal oil, and critical process systems where safety, accuracy, and long-term reliability are mandatory.

If steam is the “energy carrier” of your plant, this valve acts as the precision regulator that keeps the entire system stable.

What Is a Pneumatic Actuated Flanged Bellows Sealed Valve CF8?

Definition and industrial role

This valve is a globe valve equipped with a metal bellows seal and operated by a pneumatic actuator. The bellows isolates the process fluid from the atmosphere, completely eliminating stem leakage—one of the most common failure points in conventional globe valves.

The CF8 body material (SCS13A / AISI 304 stainless steel) provides excellent resistance to corrosion, thermal cycling, and condensate exposure commonly found in steam systems.

Why bellows sealed design matters in steam service

Steam systems are unforgiving. High temperature, pressure fluctuations, and continuous operation cause traditional packing to degrade over time. The bellows sealed design acts as a primary pressure boundary, ensuring:

-

Zero fugitive emissions

-

Stable sealing performance

-

Reduced maintenance frequency

This makes the valve especially suitable for continuous-duty steam applications.

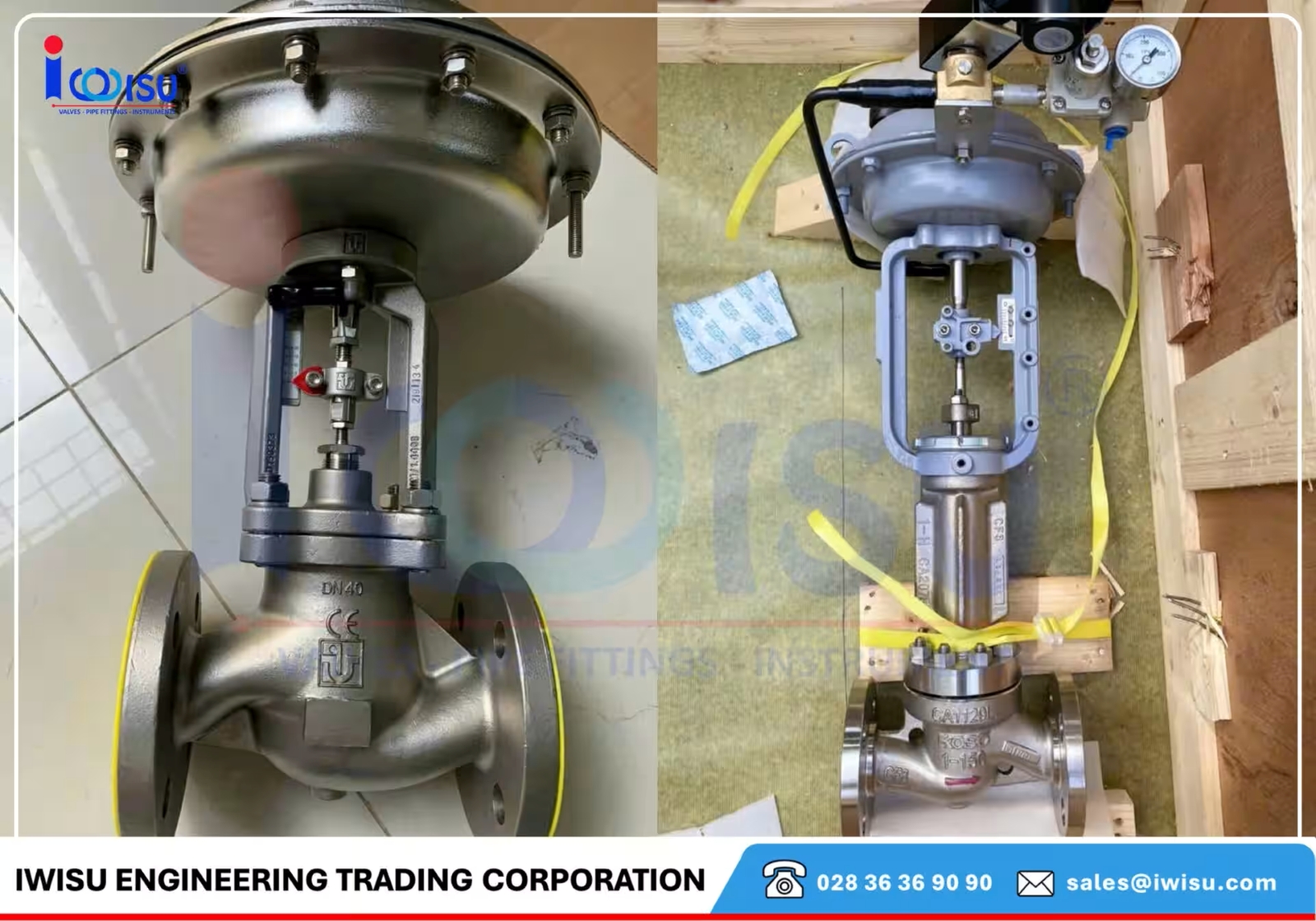

Construction of Pneumatic Actuated Bellows Sealed Globe Valve

CF8 valve body and bonnet

The valve body and bonnet are manufactured from CF8 stainless steel (SCS13A / ASTM A351 CF8). This material is commonly selected for steam lines due to its:

-

Good corrosion resistance

-

Mechanical stability at elevated temperature

-

Compatibility with condensate and treated water

Flanged ends allow secure installation and easy maintenance in pipeline systems.

Bellows assembly and secondary packing

The bellows is typically made from multi-layer stainless steel, welded to both the stem and bonnet. It absorbs axial stem movement while maintaining a hermetic seal.

A secondary graphite packing set is included as a backup seal, adding another layer of operational safety.

Trim, seat, and stem materials

Trim components are designed for durability and control accuracy:

-

Stainless steel stem with hardened surface

-

Metal seat or soft seat options depending on service

-

Optional Stellite hardfacing for severe conditions

This configuration ensures consistent control performance even under fluctuating steam loads.

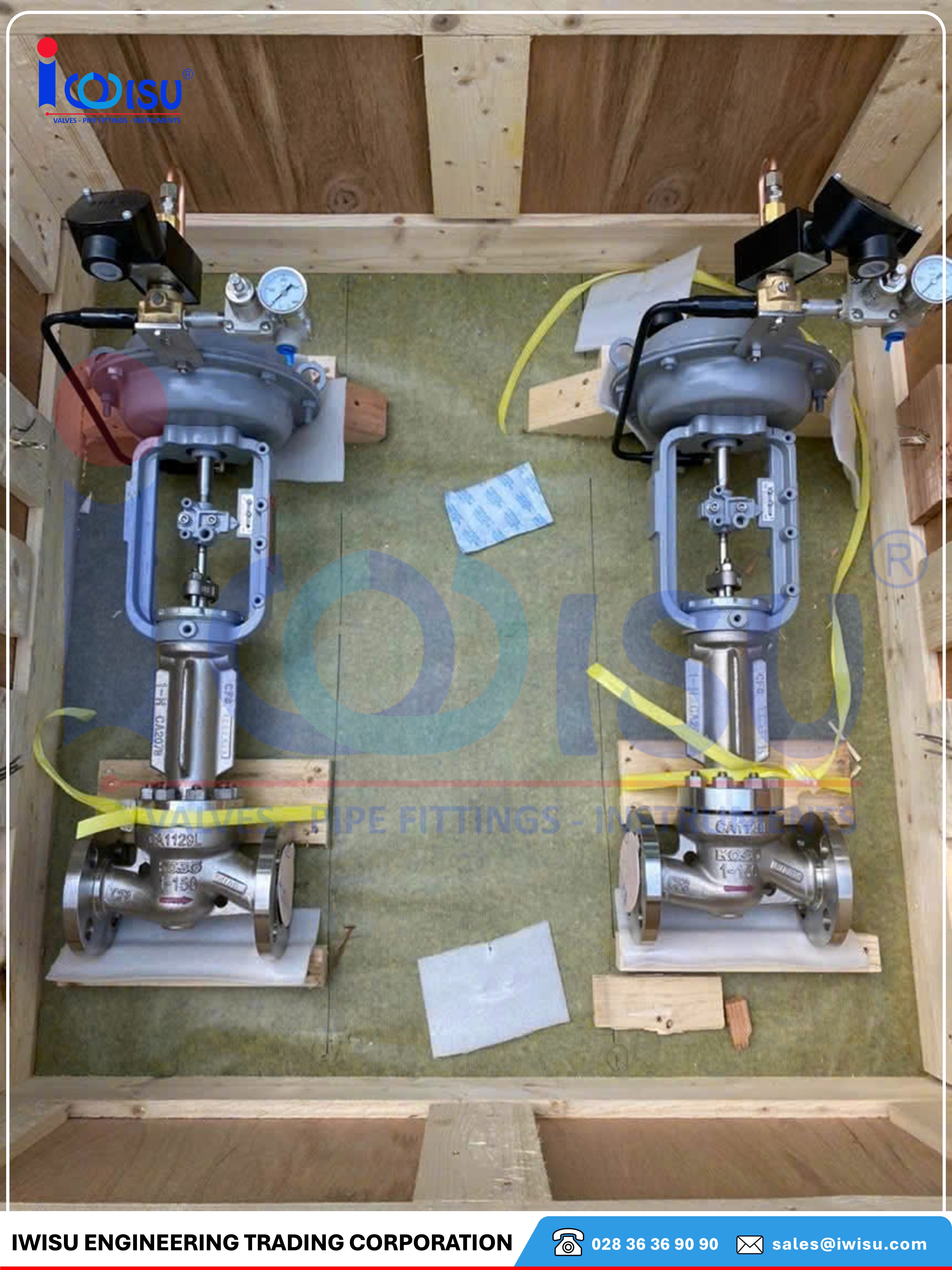

Pneumatic actuator and control accessories

The valve can be equipped with single-acting or double-acting pneumatic actuators, commonly paired with:

-

Solenoid valves

-

Positioners

-

Limit switches

This allows seamless integration into automated control systems.

Operating Principle and Control Performance

Linear motion control mechanism

Unlike rotary valves, a globe valve regulates flow through linear stem movement. The actuator modulates the plug position precisely, making this valve ideal for throttling steam rather than simple on-off duty.

Flow characteristics and modulation accuracy

Depending on process requirements, the valve can be supplied with:

-

Linear characteristic

-

Equal percentage characteristic

-

On-off configuration

This flexibility ensures stable temperature and pressure control in demanding processes.

Technical Specifications Overview

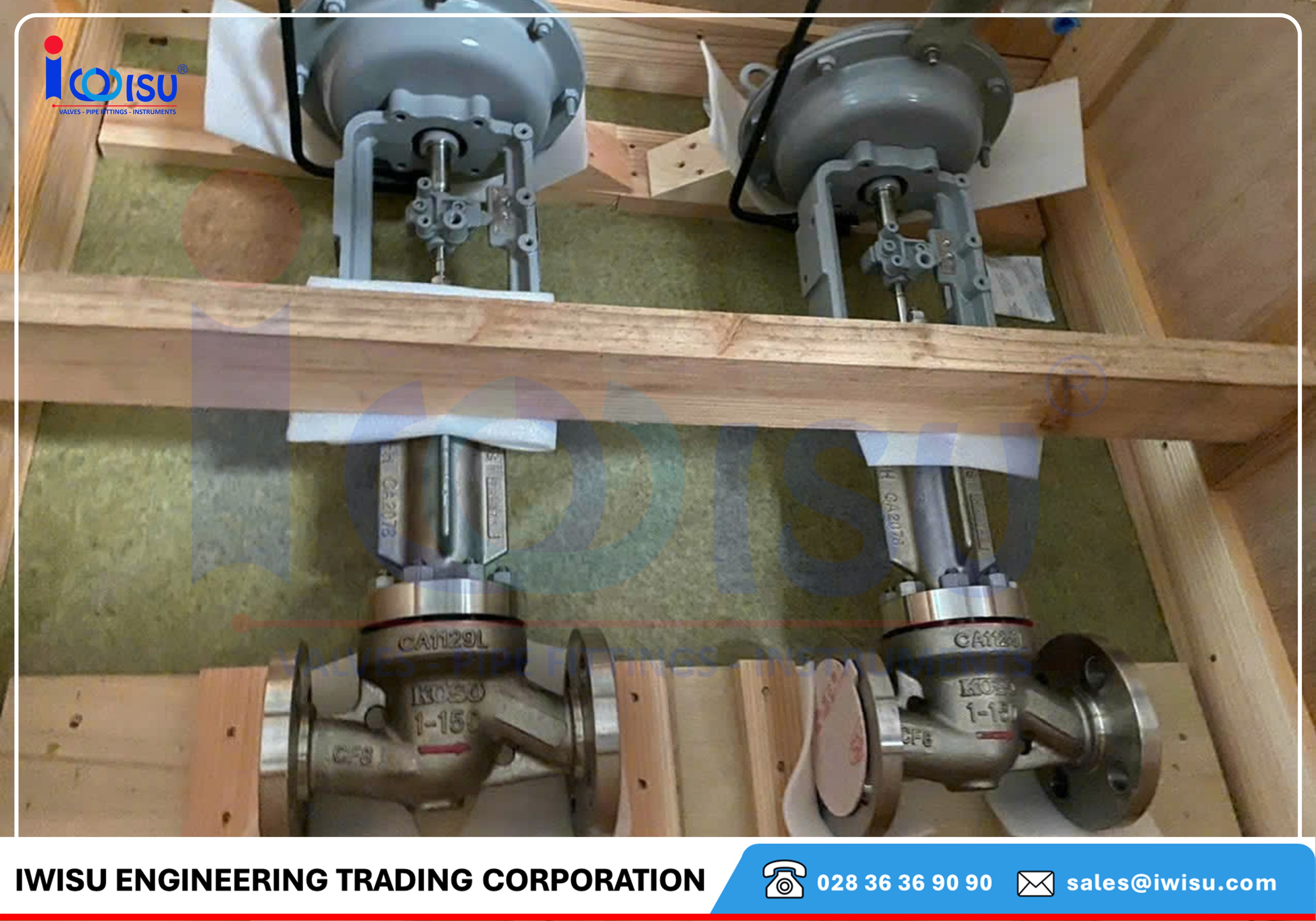

Size range, pressure rating, and standards

Typical configuration includes:

-

Size range: 1/2” to 8”

-

Pressure ratings: ANSI Class 150 to 1500

-

JIS ratings: 10K to 63K

Design and testing comply with international standards for industrial control valves.

Temperature limits for steam service

The valve is suitable for a wide temperature range, from cryogenic conditions up to approximately +538°C, making it suitable for both saturated and superheated steam.

End connections and leakage class

Available end connections include:

-

Flanged RF or RTJ

-

Butt weld

-

Socket weld

Leakage performance meets ANSI/FCI 70-2 Class VI, ensuring tight shutoff.

Typical Applications of Pneumatic Bellows Sealed Valves

Saturated and superheated steam lines

Commonly installed in:

-

Steam distribution headers

-

Heat exchangers

-

Pressure and temperature control loops

The bellows seal ensures long-term reliability even under continuous operation.

Chemical, energy, and process industries

Industries such as:

-

Power generation

-

Chemical processing

-

Food and beverage

-

Thermal oil systems

rely on bellows sealed valves to maintain safety and process stability.

Comparison with Other Valve Types

Compared to manual globe valves

Manual globe valves depend on operator consistency and packing integrity. Pneumatic bellows sealed valves offer:

-

Automated control

-

Faster response

-

Reduced human error

Compared to ball and butterfly valves

Ball and butterfly valves excel at on-off service. However, for precise steam modulation, a globe valve remains the superior choice.

How to Select the Right Pneumatic Bellows Sealed Valve

Choosing CF8 vs CF8M

CF8 (304) is suitable for most steam applications. CF8M (316) should be selected when chlorides or corrosive media are present.

Selecting trim and flow characteristic

Incorrect trim selection often results in unstable control. Always size the valve based on required Cv, not just pipe size.

Common selection mistakes in real projects

Typical errors include:

-

Oversizing the valve

-

Ignoring temperature cycling

-

Selecting on-off valves for modulating service

Avoiding these mistakes significantly improves system performance.

Conclusion

The Pneumatic Actuated Flanged Bellows Sealed Valve CF8 is a proven solution for steam systems requiring precise control, zero external leakage, and high operational safety. When properly selected and configured, it delivers long service life, reduced maintenance, and reliable performance in demanding industrial environments.

Frequently Asked Questions (FAQ)

1. Can this valve be used for superheated steam?

Yes, as long as operating temperature and pressure remain within design limits.

2. Is CF8 suitable for all steam applications?

CF8 is suitable for most steam systems; CF8M is preferred for corrosive environments.

3. Does the bellows eliminate the need for packing?

The bellows is the primary seal, while packing acts as a secondary safety seal.

4. Can a positioner be installed on this valve?

Yes, a positioner is commonly used for accurate flow control.

5. Is this valve suitable for continuous operation?

Yes, it is specifically designed for continuous-duty industrial service.

Contact IWISU today for consultation and quotations on genuine imported Pneumatic Actuated Flanged Bellows Sealed Valve CF8 products

This article was written by the IWISU engineering team and reviewed by Le Huy Do, a technical expert with over 10 years of hands-on experience in supporting, consulting, and installing industrial valve systems — particularly high-quality imported floating ball valve, widely used in both large and small industrial projects in Vietnam. All information shared is based on practical experience, installation work, and real operation at factories.

IWISU Engineering Trading Corporation is a trusted distributor of industrial valves, flanges, and pipe fittings in Vietnam. We supply products for major projects in sectors such as oil & gas, chemical, food processing, and many other industries. IWISU takes pride in being a reliable supplier of valves and piping components for leading contractors in Vietnam such as Thaco, PetroVietnam, Acecook, and others.

We are also an authorized distributor for officially imported products from countries including Korea, China, Japan, and Europe, featuring renowned brands such as ANIX, ASCO, REGO, AUTOMA, HSE, Fluonics, SAMWOO, Lenor, BV (BVALVE), Swissfluid, and Zuercher Technik.

All products come with full Certificates of Origin (CO) and Certificates of Quality (CQ), ensuring premium quality, competitive pricing, and fast delivery. IWISU is committed to long-term cooperation and delivering sustainable value to all partners and customers across Vietnam.

For inquiries, consultation, or quotation requests, please contact us:

-

Email: sales@iwisu.com

-

Hotline: 028 36 36 90 90 – 0908 217 288

-

Website: https://iwisu.vn

Visit our website to explore a full range of industrial valves, flanges, pressure gauges, and other imported equipment at: thegioivalve thietbinhapkhau thegioimatbich