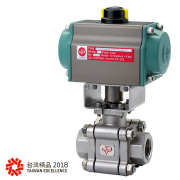

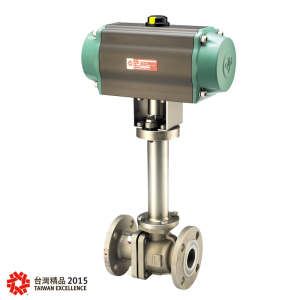

FLOATING BALL VALVE – JBF CRYOGENIC SERIES

JBF CRYOGENIC SERIES

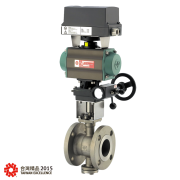

JDV BALL VALVE

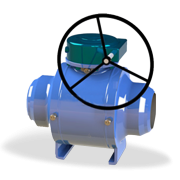

FLOATING BALL VALVE – JBF CRYOGENIC SERIES

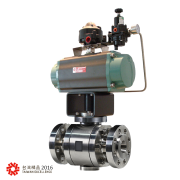

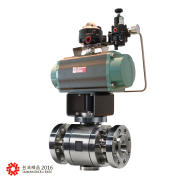

Cryogenic Valve – Floating Type Soft – Metal Seat Ball Valve

Full Bore Two – Piece Flanged Ends

JIS 10K – JIS 20K ASME CLASS 150 – CLASS 300 DIN PN16 – DIN PN40

In order to satisfy the ever growing needs of high-quality cryogenic valves for a wide range of industries, our skilled engineers, who already possess an extensive experience in critical applications, designed the JBF/JBFM Cryogenic Series.

Based on the successful and renowned design of the JBF/JBFM Series, our cryogenic products offer an unmatched level of reliability, stability and most importantly safety, whatever the low temperature medium may be:

Applicable Standards

-

Body Material: Standard in LCB, LCC, LC9, CF8, CF8M. Special materials are available according to requirements.

- Nominal Size: 1/2” to 6” (DN15 to DN150)

- Pressure Rating: JIS 10/20K ASME CLASS 150/300 DIN PN16/40

- End Connections: RF

- Temperature Range: Soft Seat: -321~356°F (-196~180°C) / Metal Seat: -321~661°F (-196~350°C)

- Face-to-face Dimensions: JIS B2002 / ASME B16.10 / EN 558 Series 14/15

- Flanged Dimensions: JIS B2220 / ASME B16.5 / EN 1092-1

- Body Pressure Test: JIS B2003 / API 598

- Seat Leakage Test: BS6364

-

Casting: MSS-SP-25 / MSS-SP-55

Product features

- Available in soft and metal seats to meet the requirements of all kinds of industries.

- Highly precise machining enabling the seat leakage to reach the strict requirements of the BS6364 standard.

- Extended stem protecting efficiently the actuator from the frozen temperature of the medium.

- Spring-loaded design keeping the metal seat in tight contact with the ball, even at low pressure.

- Design with a larger ball, to offer the best sealing efficiency.

- Upstream relief hole on the ball, preventing any overpressure in the cavity.

- Anti-static design.

- Anti-blowout stem design.

- ISO 5211 Mounting Pad design.

Product Spec: Catalog

Certification

- Applus RTD BS6364 -196°C cryogenic test

- Applus RTD BS6364 -196°C cryogenic test

- Applus RTD BS6364 -196°C cryogenic test

- Applus RTD BS6364 -196°C cryogenic test

- DCI BS6364 cryogenic test

- DCI High Temperature Test

- DNV-CE Certificate 2017.04.15

- DNV-CE Certificate 2017.04.15