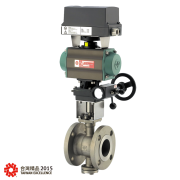

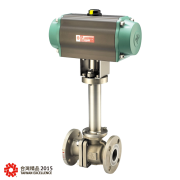

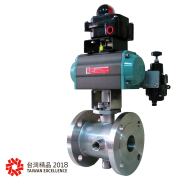

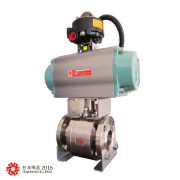

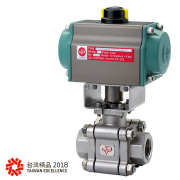

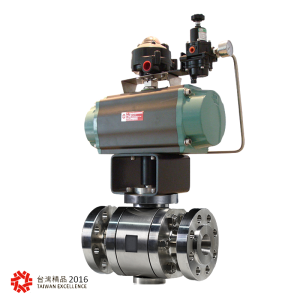

JBT Series Trunnion Type Soft Seat Ball Valve

JVD CONTROL VALVE

JBT Series Trunnion Type Soft Seat Ball Valve

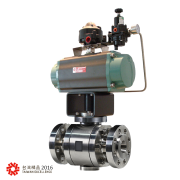

Trunnion Type Soft – Metal Seat Ball Valve

ASME CLASS 150 – CLASS 300 – CLASS 600 – CLASS 900 – CLASS 1500 – CLASS 2500

The JBT & JBTM Series are Trunnion-mounted ball valves designed with vanguard engineering and highly sophisticated technology. Our in-house High Velocity Oxygen Fuel-sprayed hard faces allow them to defy the toughest operating conditions, such as high pressure, abrasive and corrosive mediums, slurries, etc. Successfully used in the Oil & Gas industry, Refineries and Power Plants, these API 6D certificated valves provide an outstanding tightness, stability, safety and reliability that exceed most industry standards.

Applicable Standards

- Body Material: Standard in WCB, CF8, CF8M. Other materials are available according to requirements.

- Nominal Size: 2” to 24” (DN50 to DN600)

- Pressure Rating: ASME CLASS 150/300/600, 900/1500/2500 on request.

- End Connections: RF / RTJ

- Temperature Range: Soft seat: -320~482°F (-196~250°C) / Metal seat: -320~932°F (-196~500°C), higher temperature on request.

- Face-to-face Dimensions: ASME B16.10

- Flanged Dimensions: ASME B16.5

- Body Pressure Test: ASME B16.34 / API 598 / API 6D

- Seat Leakage Test: Soft seat: ASME B16.34 / API 598 / API 6D / Metal seat: ANSI/FCI70-2 Class V in standard, Class VI in option.

- Casting: MSS-SP-25 / MSS-SP-55

- Fire Safe Design: Certificated according to API 607 / API 6FA

Product features

- True bidirectional design and wide temperature range satisfying all applications.

- Cavity pressure relief design protecting against any excess of pressure in the body cavity.

- Trunnion ball design ensuring a tight contact between seats and balls, and allowing the valves to withstand extremely high pressures.

- Single Piston seat rings that guarantees the self-relief of the body cavity in case of overpressure.

- Double piston design in option, securing both upstream and downstream sealings.

- Optional double block and bleed design ensuring a safe isolation simultaneously on both upstream and downstream seats.

- Splined stem design strengthening the trim to withstand heavy torques under high pressure drops.

- Emergency sealant injection design on request to restore the seat or packing integrity immediately.

- Optional drain plug device to empty the cavity or to detect any leakage.

- Body gland providing a trustworthy anti-blowout function and an easy maintenance.

- Several alternatives of soft and metal seats to meet any kinds of requirement.

- Optional purge device guaranteeing a complete cleaning of the body cavity.

- Fire safe design according to API 607 or API 6FA.

- Anti-static device.

- ISO 5211 Mounting Pad design.

Product Spec: Catalog

Certification

- DNV-CE Certificate 2017.04.15

- DNV-ISO 9001-2008 Certificate 2017.02.25

- Fire-safe test API 6FA 3 Edition

- Fire-safe test API 6FA 3 Edition

- Fire-safe test API 6FA 3 Edition

- Fire-safe test API 607 6 Edition

- Fire-safe test API 607 6 Edition

- SIL3