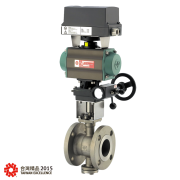

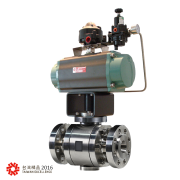

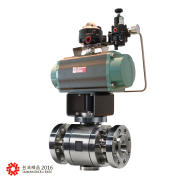

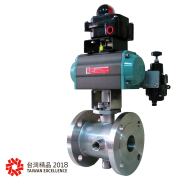

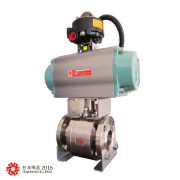

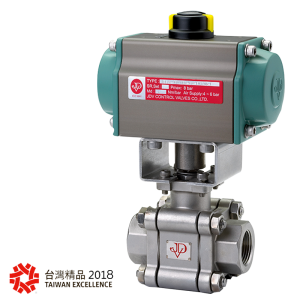

JBSM Series Floating Metal Seat Ball Valve

VAN ĐIỂU KHIỂN JDV SERIES JBSM

JDV VALVE – JBSM SERIES

JBSM Series Floating Metal Seat Ball Valve

- Floating Type Metal Seat Ball Valve

- Full Bore Three-Piece Threaded / Welded /Flanged Ends

To answer the growing demand of reliable and robust metal-seated threaded & welded ball valves, our experienced engineering teams designed the JBSM Series, meeting the requirements of the most challenging industries: Oil & Gas, Refineries, Petrochemical & Chemical Industries, Power Generation, Pulp & Paper, Mining, etc. Strengthened by our unique design and coated with our own High Velocity Oxygen Fuel technology, they are successfully used under the most extreme conditions, such as high temperature, high pressure, corrosive and/or abrasive fluids, slurries, etc.

- Body Material: Standard in WCB, CF8M. Other materials are available according to requirements.

- Nominal Size: 1/2” to 2” (DN15 to DN50)

- Pressure Rating: ASME CLASS 600

- End Connections: Threaded / Socket Weld / Butt Weld / Flanged

- Temperature Range: -20~661°F (-29~350°C), higher temperature on request.

- Flanged Face-to-face Dimensions: ASME B16.10 / EN 558 Series 5/14

- Flanged Dimensions: ASME B16.5 / EN 1092-1

- Body Pressure Test: ASME B16.34 / API 598

- Seat Leakage Test: ANSI/FCI70-2 Class V in standard, Class VI in option.

- Casting: MSS-SP-25 / MSS-SP-55

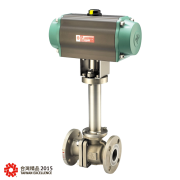

Product features:

- Bidirectional design (with preferred direction), adequate for any kind of backflow application.

- Oversized stem design preventing any deformation from high pressure or high temperature.

- Several alternatives of coating, suitable for slurries and very corrosive mediums.

- ASME Class 600 wall thickness design, enabling it to withstand severe operating conditions.

- Scraper seat design in option, to avoid any accumulation of fluid deposit on the ball surface.

- Design with a larger ball to provide the best sealing, in order to reduce any leakage.

- Inconel® spring design ensuring a tight contact between the ball and the seats.

- Live-loading design eliminating any stem leakage and providing a longer life cycle.

- Anti-static design.

- Anti-blowout stem design.

- ISO 5211 mounting pad.

Product Spec: Catalog

- DNV-CECertificate 2017.04.15

- DNV-ISO 9001-2008 Certificate 2017.02.25