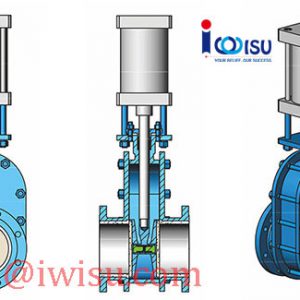

CERAMIC DOUBLE DISC VALVES

Tổng quan:

Công ty IWISU là một trong những công ty hàng đầu ở Việt Nam về phân phối Van với các thương hiệu nổi tiếng trên thế giới như: ANIX, JC VALVE, FOYO VALVE, SAMWOO, BONNEY FORGE, SWISS FLUID, JDV CONTROL VALVE, MARIANI, KITZ, EBRO VALVE

Trong đó sản phẩm DOUBLE DISC GATE VALVE được công ty nhập khẩu và phân phối tại Việt Nam.

Chất lượng của DOUBLE DISC GATE VALVE không chỉ đáp ứng nhu cầu của khách hàng mà còn mang lại sự tin tưởng, uy tín về sản phẩm do công ty phân phối.

Three piece bodies of Ceramic Double Disc Valves are very easy for assemble and reliable for maintenance.

Specification:

| Type | Double Disc Valves Gate Valve |

| Size | DN25-DN400(1”-16”) |

| Pressure Rating | PN10,PN16,PN25,PN40, CL150, CL300 |

| Body Material | WCB, CF8 |

| Trim Material | WCB+Al2O3 Ceramics, WCB+ZrO2 Ceramics, WCB+Solid Tungsten Carbide,WCB+Stellite |

| End Connection | Flanged type, Wafer Type, EN1092-1, DIN 2501, ASME B16.5 |

Typical Applications:

In many bulk material handling systems, such as coal fired power plant, steel plant, cereals transport system, cement transport systems, etc., generally in these applications, pneumatic conveying method is used to reduce manpower demand, and improve system efficiency and reliability. But abrasion of valves is a big problem that causes customers a lot trouble.

The valve sealing surface and flow path of these valves are destroyed seriously by high speed solid materials. FOYO develops Ceramic Double Disc for these applications which works quite well for coal fired power plants all over the world.

Double Disc Gate Valves are suitable for any bulk materials handling system including the mediums listed as below: Silicon Powder, Alumina Powder, Coal Powder, Cement, Lime Stone Powder, Magnesium Powder, Quartz Sand, Metallurgical dust, Ores, Fly Ash, Granules.

Ceramic Knife Gate Valves

Design Features:

Product type

The Ceramic Gate Valve is ceramics-to-ceramics sealing, also named as parallel double disc valve, or ceramic double disc valve or ceramic double gate valve.

The standard end connection of ceramic double disc valves is flanged type, but if the installation space is limited, wafer type is available.

Three piece bodies of Ceramic Gate Valves are very easy for assemble and reliable for maintenance.

Self-cleaning disc design allows disc to move freely and avoid being scratched by solid particles.

Temperature range

Usually working temperature of pneumatic conveying system is not so high, but under some conditions like economizer valves in coal fired power plant, the working temperature may be up to 450 ℃. Then special design of ceramics and packing material will be considered.

Normal working temperature of Ceramic Double Disc Valves: -29 °C ~ +200 °C

High temperature design of Ceramic Double Disc Valves: -29 °C ~ +450 °C

Ceramic Rotating Double Dsic Valves

Valve tightness

The tightness of valve is very important. FOYO has advanced ceramic processing technology and skilled technicians. All ceramic sealing faces of the Ceramic Double Disc Valves are well ground and polished, which ensure Class V leakage as per FCI 70-2.

Other tightness rates upon request.

FOYO Ceramic Double Disc Valves have much longer service life than the other similar products.

Design standards

Valve body ASME B16.34

Face-to-Face: Manufacturer’s Standard, customized length of Ceramic Double Disc Valves is available.

Valve Testing: API 598